A Glimpse Into Our Manufacturing Process

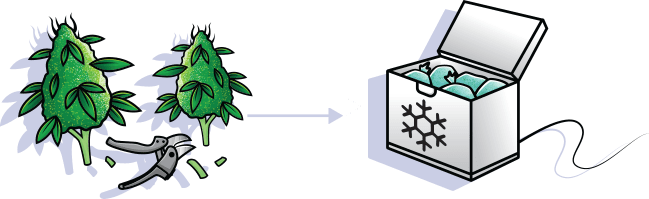

Step 1

Source material from the best cultivators we can find. Freeze this material within minutes of harvest to preserve the profile of the strain. Keep the material at sub-zero temperatures until it is ready for the next step in its journey.

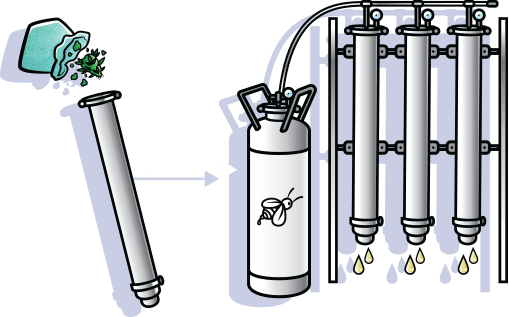

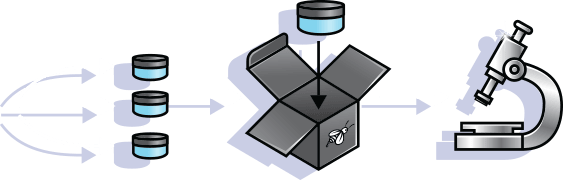

Step 2

Extract the cannabinoids and essential oils (flavonoids and terpenes) from the plant material using state-of-the-art machines which utilize food-safe solvents and recycle them.

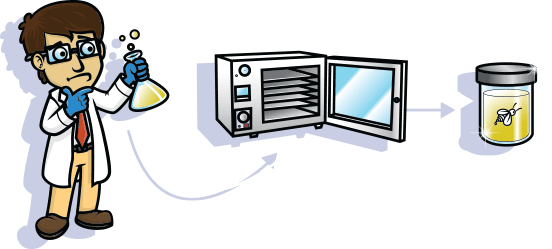

Step 3

Remove any residual solvent in the extract to make it safe and enjoyable for consumption. This is achieved by placing the extract in a vacuum oven to expedite the degassing process. After this, the concentrate is ready to be made into sauce, butter, diamonds, or simply kept as shatter.

Step 4

When the extraction is in its final form, it is ready to be packaged and boxed. All products must then be picked up from Beezle HQ by a licensed distributor who will quarantine batches and have them sampled by a licensed testing agency.

Step 5

After all state-required testing is completed by the lab, the product is ready to be distributed to retail shops around the state and enjoyed by Beezlers like yourself! We hope you enjoy the result of this farm to rig affair.